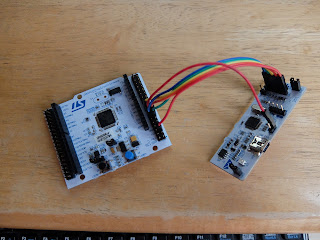

Battery holders and ST-Link

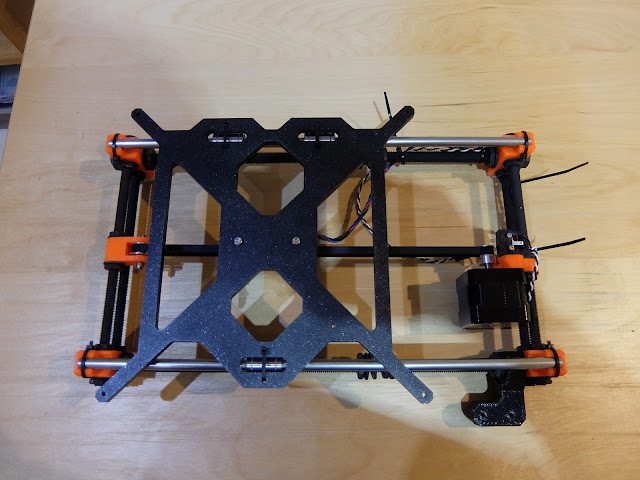

I'm printing a new version of my round robot chassis with PETG. I had one initial objective: to add better battery enclosures, because the batteries on the first one just fell out. So I added some integral ones. I looked around Thingiverse and found these , which led back to these . I actually designed my own: since I needed to resize to CR123, and didn't find the SCAD files all that readable: full of magic numbers... I used the clips from the second design, because they were better specified, and not expensive from rs-components. Anyway, I printed that version in PETG. When I came to get it off the plate, the base layer just stayed on the plate: the adhesion between the plate and the base was greater than the adhesion between the shell and the filling! I've refactored the chassis quite a lot to deal with that. The latest iteration is printing now. The other change was to support a Nucleo 64 board like the STM32F303RE one. I've managed to remove the programmer, ...