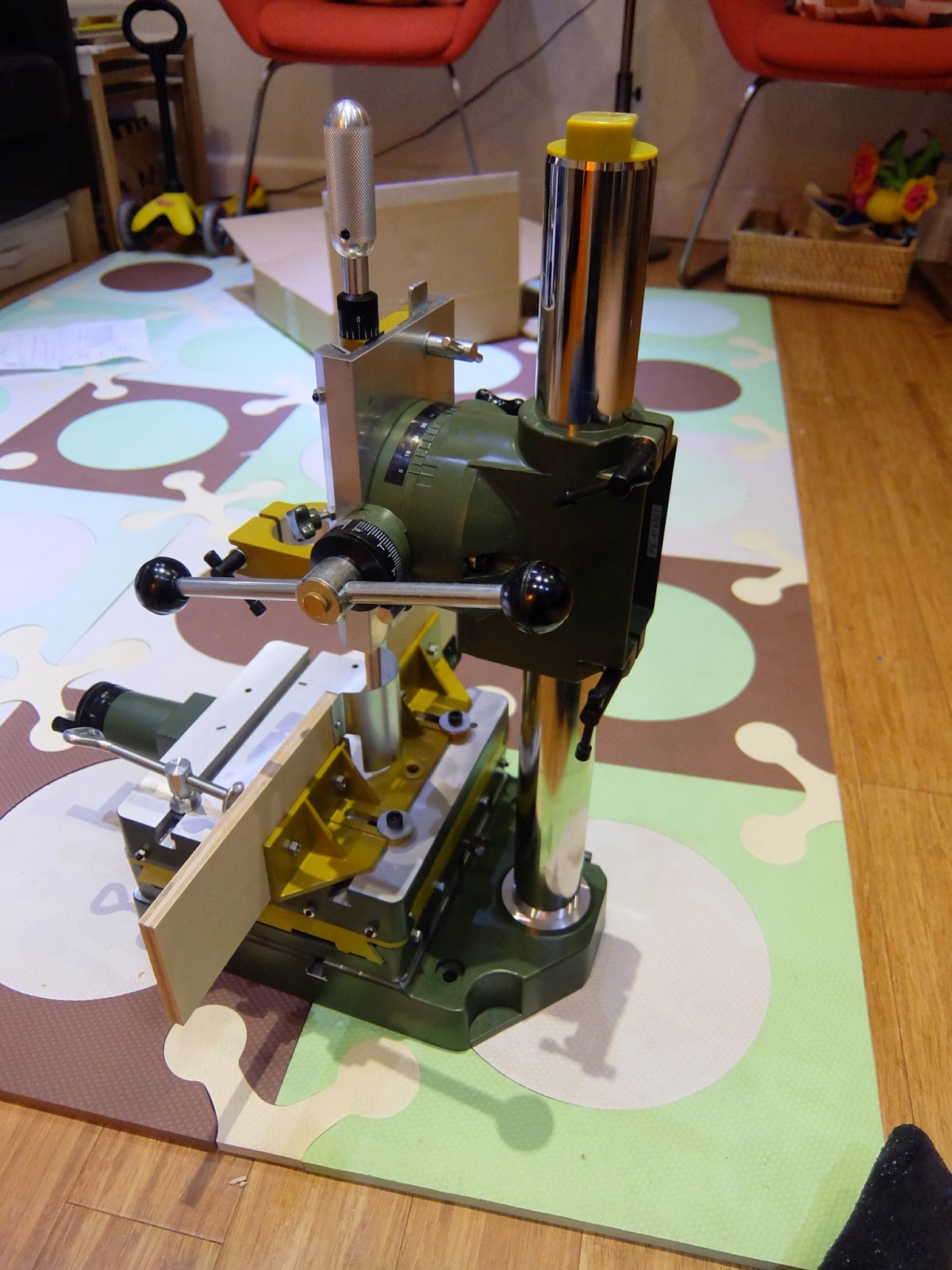

A quick look at the Proxxon Micromot KT 150 and Proxxon BFB 2000

I brought these home today. Here's a couple of photos: I'm photographing it in the living room, because my shed is filled with boxes, as I'm re-doing the shelving to be more flexible, and lining the walls at the same time. It might be a while before I actually use this! The first picture is the really illustrative one. Just look how solid it is! The movement in all the axis is very smooth. It comes with all the parts greased with something odourless, clear and colourless. I think I'll have to find out what it is. There are a few promising details: The head can rotate, but to zero it, you can lower it down onto the table: the bottom is flat. If you do that, you'll find the zero marker is perfect anyway. I think the fence seems pretty good: certainly it's a quick way to work with wood, and it certainly looks like you could use this as an inverted router table for small work. Perhaps you could even slide something larger along the fence, with the guard se...