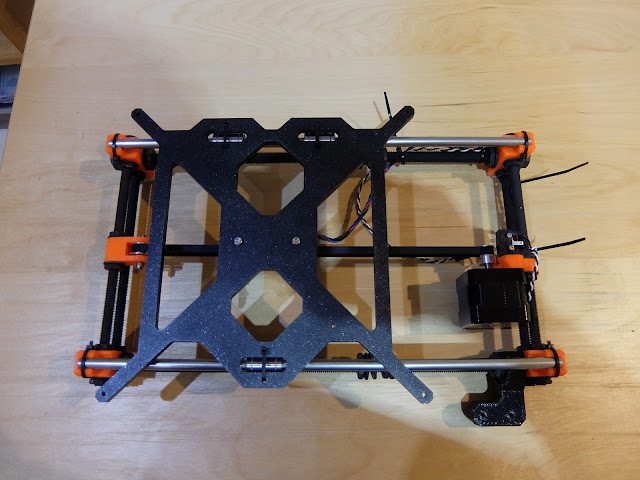

I'm quite a long way though the build. I spent about 2 hours on it on Tuesday night and another 2 hours last night. I have the extruder mounted on the X-Axis, so basically all the mechanical parts are done. I've messed up a few things: I couldn't get the rods fully into the X-Axis motor mount, until I resorted to using a hammer. Also, when I slid the X-Axis on, I wrecked one of the bearings. Fortunately I had a spare lying around. Here are some of the sub-assemblies: the Y-Axis: The troublesome, too long X-Axis: I think I have the hang of the instructions now. It's pretty easy to not get everything oriented correctly: for example, the cable management depends on the correct orientation of the motors and fans. I still managed to put the extruder fan in the wrong way the first time. It's an annoying mistake, because where the screws are tapped into plastic parts they are very stiff! I have to say, I feel the whole thing is a bit flimsy, and I'l...