Work Holding, and tapping is surprisingly easy

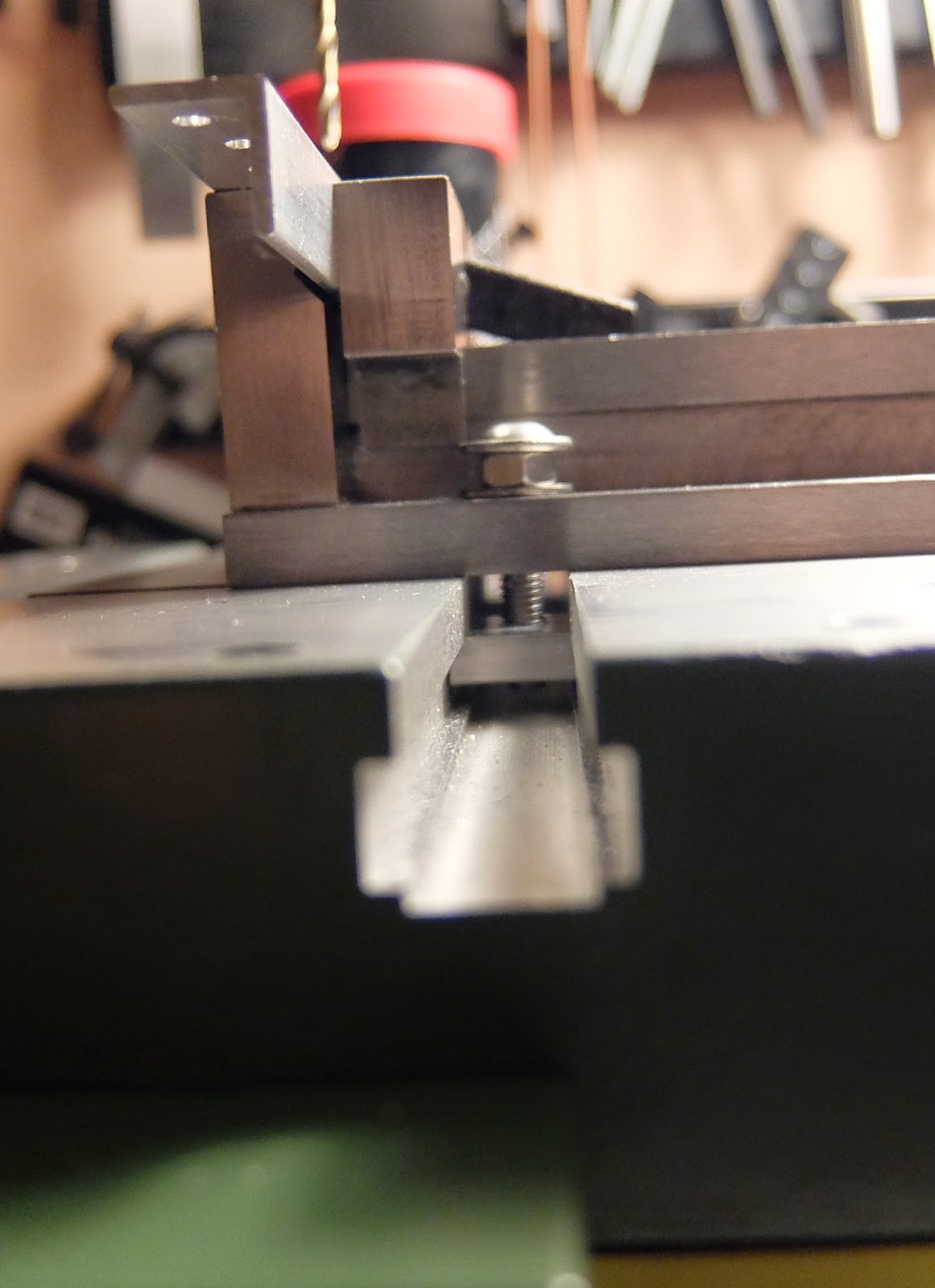

I bought this little machine vice from Axminster, before I had the new milling stand and compound table. The reason was the long slots, which would have made it easy to position correctly in the drill press. Unfortunately, the vice slots accommodate a maximum of an M6 bolt. It comes with a bolt with an oversize head, but this is designed for a bigger table: probably a 12mm slot. It turned out not to be hard to fix this however: make an oversized nut with an M5 thread, out of some 5mm thick aluminium flat bar. Here it is:

I've never tapped a whole before, and I just have a basic tap and die kit, but actually my first attempts worked fine. Aluminium is of course quite soft, and with a bit of wax on the tap, I got all the way through 5mm in one go.

I've carefully fixed the vice square on the table, and don't have to move it - I can just move the table:

The vice isn't perfect: it takes a bit of care to make sure the back jaw is what you are using to keep things square: the moving jaw doesn't stay very square. Something different would be preferable now I have the compound table, but this is OK for now.

I was planning to centre punch holes and use a centre finder, but I'm not at the moment: I just rotate the drill bit so the point faces which ever axis I'm trying to adjust. The final test is to push down with the bit and make a little mark. If I then just drill, the result is sufficiently reliable. I've just drilled some bits of angle, with the hole overhanging the edge of the vice.

I also need to drill bits of work like this:

Which is an axle block. The holes go all the way through, so I needed to avoid drilling into the bottom of the vice. I actually just used a second block as a sacrifice, but that was fiddly, and didn't give very accurate results: there wasn't enough clamping force on the work itself.

I think the correct solution is a step vice jaw, Or perhaps something like this quick clamp. The latter probably isn't small enough: this is 10mm square bar, and I'm guessing the quick clamp's minimum is 1/2". If I had a milling spindle, I guess this is something I could make, but it would have to be made very accurately. The step vice jaw seems like such a good solution, you'd expect it to be widely available. Sadly I've only found US sellers so far. At least it doesn't matter if it's dimensions are imperial!

I've never tapped a whole before, and I just have a basic tap and die kit, but actually my first attempts worked fine. Aluminium is of course quite soft, and with a bit of wax on the tap, I got all the way through 5mm in one go.

I've carefully fixed the vice square on the table, and don't have to move it - I can just move the table:

The vice isn't perfect: it takes a bit of care to make sure the back jaw is what you are using to keep things square: the moving jaw doesn't stay very square. Something different would be preferable now I have the compound table, but this is OK for now.

I was planning to centre punch holes and use a centre finder, but I'm not at the moment: I just rotate the drill bit so the point faces which ever axis I'm trying to adjust. The final test is to push down with the bit and make a little mark. If I then just drill, the result is sufficiently reliable. I've just drilled some bits of angle, with the hole overhanging the edge of the vice.

I also need to drill bits of work like this:

Which is an axle block. The holes go all the way through, so I needed to avoid drilling into the bottom of the vice. I actually just used a second block as a sacrifice, but that was fiddly, and didn't give very accurate results: there wasn't enough clamping force on the work itself.

I think the correct solution is a step vice jaw, Or perhaps something like this quick clamp. The latter probably isn't small enough: this is 10mm square bar, and I'm guessing the quick clamp's minimum is 1/2". If I had a milling spindle, I guess this is something I could make, but it would have to be made very accurately. The step vice jaw seems like such a good solution, you'd expect it to be widely available. Sadly I've only found US sellers so far. At least it doesn't matter if it's dimensions are imperial!